随着夏季,一个节气大暑的到来,天气也来到了一年中超热的时期。大家在做好防暑的同时也要关注一下爱车,因为车辆长期处于高温酷暑的环境下一些使用频繁或者负荷较重的系统装置容易发生故障。油井为你带来夏季养护贴心建议,伴您安然度夏。

夏季用车保养,轮胎、空调系统、发动机等此类部件尤为重要,持续的高温容易引起轮胎气压升高,会增加爆胎风险,有长时间行驶需求的车主可以适当降低轮胎气压;而空调更是夏季的必需品,定期的检查与清理是非常有必要的。同时,长时间使用空调要注意内外循环的切换,保持车内空气清新流通。

1、大暑驾到骄阳照,爱车保养早知道

持续不下的高温天气,不免让人心烦意乱,而我们的爱车也很容易长时间处于高温环境下,这便导致汽车的“心脏”发动机的工作环境变得相当恶劣,在炎炎烈日下发动机所要承受的压力更是可想而知。因此选择、适合爱车的润滑油尤为重要,也是夏季发动机保养的关键。

2022年油井隆重推出超SynthTech合科/SynthGold合金,油井SynthTech合科、油井SynthGold合金产品性能全面升级,并且全面适用国六b(该机油的磷硫含量及硫酸盐灰分含量符合ACEA C2/C3/C5规格要求的上限值,可延长尾气后处理系统的使用寿命以满足国六b要求)排放标准及以下车型。

全新油井SynthTech合科/SynthGold合金贯穿6大关键领域(耐高温,抗氧化,提高分散性,增强耐久性,保持活塞清净,减少低速早燃)性能表现超越行业限值60%(基于实验室测试),全面激发高昂表现,并符合“碳中和”(符合PAS 2060)可持续发展理念。同时,全新油井SynthTech合科/SynthGold合金系列产品还增强了OEM认证,与合作伙伴共同开展技术研发,度身定制高品质的润滑油产品。全新油井SynthBenz FE合金0W-20产品符合ACEA新C6标准,奔驰MB229.71,宝马BMW LL-17FE。全新油井SynthTech合科/SynthGold合金用实力展现“双层油膜技术”的超强表现,激发引擎高昂性能表现。

全新油井SynthTech合科/SynthGold合金拥有,突破性的双分子锁合技术能在发动机表面形成具智能感应的强力保护层,显著降低热车及启停时的磨损,超越行业限值50%(热车的幅度基于程序IVA测试中与API SN磨损限值的对比;启停时的幅度基于CEC OM646LA测试中与ACEA磨损限值的对比),真正做到未启动,先保护,时刻保护。全新油井双层油膜启停保显著降低热车及启停时的磨损,超越行业限值50% 4,在频繁启停路况下可每年节省50L燃油(基于ISP所进行的以下测试:在EUDC(高速道路),EPA 欧洲城市道路循环(城市道路)以及油井Ultra-Idle循环测试(模拟拥堵道路)中与10W-40行业参比油相对比。假设前提:年度行驶里程为12,000公里;驾驶路况60%为高速道路,30%为城市道路以及10%为拥堵道路。实际路况条件下的结果可能会因为车辆类型、驾驶条件以及驾驶习惯的不同而有所变化),真正做到未启动,先保护,频繁启停时刻保护。全新油井混合动力通过混合动力汽车测试(基于油井内部关于丰田普锐斯在EPA欧洲城市循环工况测试),显著降低低温及启停时的磨损,超越行业限值50%(低温时的幅度基于程序IVA 测试中与API SN磨损限值的对比。启停时的幅度基于CEC OM646LA测试中与ACEA磨损限值的对比),真正做到未启动,先保护,混合动力时刻保护。除此之外,全新油井合金0W-40及合金0W-20可以额外提升气缸磨损保护 (减少发动机损伤概率),超越行业限值80%(基于CEC OM646LA测试中与ACEA磨损限值的对比)。

2、开盖有奖,油井邀您共赴英超观赛之旅

此外油井推出的“合科甄品,开盖有奖”特别活动将持续至2022年12月31日。凡购买带有“合科甄品,开盖有奖”标志的油井产品,使用手机微信“扫一扫”扫描瓶盖内活动二维码参与活动,便有机会获得一张2022-2023赛季英超联赛现场球票及单人往返机票等精彩好礼。

,,油井提醒广大车主朋友们,酷热天气除了对爱车本身的考验,也容易引起司机和乘客身体不适。炎炎夏日,大家要呵护好自身健康,杜绝疲劳驾驶,多补充水分,注意防暑降温。

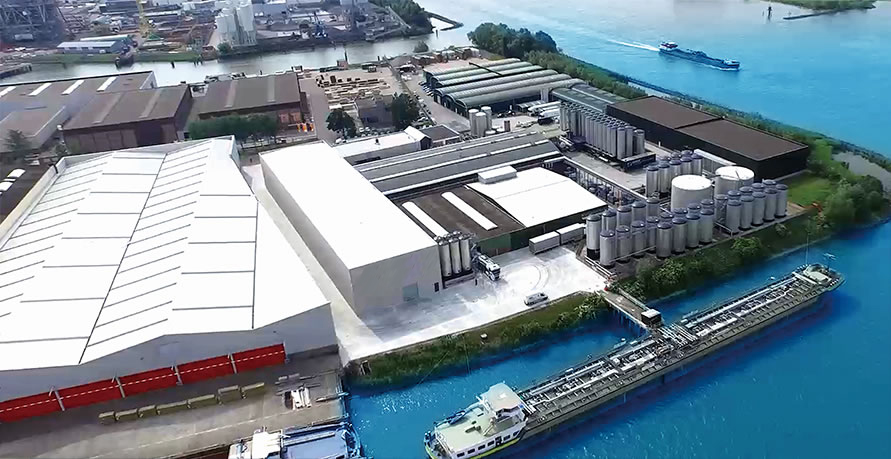

油井润滑油(De Oliebron)作为欧洲大型独立润滑油制造商。成立于荷兰鹿特丹,至今天已有130多年历史,在德国与荷兰境内以及亚太都有独立润滑油制造基地,凭借超强的研发、质保、供货能力成为欧洲宝马、奔驰、大众、保时捷等全球领.先汽车品牌初装油供应商,同时也是,壳牌在欧洲市场唯.一定点供应商。公司先后获得ISO 9001:2008、ISO 14001:2004以及OHSAS 18001:2007等国际质量标准认证,并于2016年获得欧洲权威机构NBSA颁发的“成功润滑油生产商得主”称号。产品的,性能得到欧洲汽车制造协会(ACEA)的高度认可及广泛推荐!

Introduction of De Oliebron Brand

De Oliebron is a large independent lubricant manufacturer in Europe. Founded in Rotterdam, theNetherlands, and headquartered inGermany, the Company has independent lubricant manufacturing bases inGermany, theNetherlands, and the Asia-Pacific regions with a long history of more than 130 years. Thanks to its strong capabilities in R&D, quality assurance and product supply, the Company has become a lubricant supplier of global leading automakers including BMW, Benz, Volkswagen and Porsche in Europe, and is also Royal Dutch Shell’s only designated supplier in the European market. It has successively passed ISO9001: 2008, ISO14001: 2004, OHSAS18001: 2007 and other international quality standard certifications, and in 2016, was awarded the "Most Successful Lubricant Manufacturer" by NBSA, a European authority. The superb performance of our products has been highly recognized and widely recommended by the European Automobile Manufacturers Association (ACEA)!

De Oliebron offers more than 750 kinds of lubricants and greases, which can satisfy the various needs of global users. The Company offers the newly developed engine lubricants, in addition to the most suitable engine lubricants for heavy-duty racing cars, motorcycles and agricultural vehicles. De Oliebron can also provide many other products which can cover almost all industrial lubrication applications. The Company will launch all the lubricants into the global market so as to meet the various needs of users.

With its extensive experiences in the production and R&D of lubricants, De Oliebron has developed the double-layer oil film adhesion technology to produce the lubricants which can create a double-layer oil film for full protection and adapt to all weather conditions, all road conditions and other extreme environments, and therefore maintained a leading position in the industry. The double-layer oil film adhesion technology is applied to generate the independent and complementary double-layer thin oil film on the metal surface of engines. While having good fluidity, the double-layer lubrication oil film has a good protection feature which can effectively reduce damaging friction and wear, lower operating temperature, improve work efficiency, reduce power consumption, gasoline consumption and operating noise, and extend the life of friction parts, thereby achieving the goal of extending the life of engines. The cutting-edge technology of De Oliebron enables lubricant molecules to cling on metal surfaces to form a strong protective oil film, which can effectively reduce engine jitter and noise, bring a comfortable and quiet driving experience. While decomposing harmful deposits thoroughly, a double-layer isolation film can also be generated on the surface of small molecules of pollutants to wrap them firmly and avoid their re-aggregation, and have them evenly distributed in lubricants, so that engines can always operate in a clean working environment, which effectively prevent the erosion of deposits and reduce carbon deposition during combustion.

The quality of lubricants is usually judged by the official OEM certification of major manufacturers, De Oliebron has passed the latest and most OEM certifications, which brings it with a unique advantage over other lubricant manufacturers. All such quality certificates may be made available to customers upon request.

De Oliebron believes that product development is one of the most important cornerstones for its success, and continues to vigorously develop products with a longer lifespan. The quality of lubricants is usually judged by the official OEM certification of major manufacturers. The Company has developed the ECO products and XHydraulic production lines, which have contributed to the creation of beter environment. Product development is an ongoing process. De Oliebron has undertaken to global customers that it will continue to drive innovations in lubrication technology and stay concerned about environmental protection!

Going forward, De Oliebron Group. will set up its Asia-Pacific headquarters in Shanghai, a branch in Beijing and Foshan, Guangdong, the central China office in Wuhan, the southwest China office in Chengdu and the storage and distribution center in northwest China, and take Shenyang as the core radiation circle in Northeast China, thus establishing an overall business presence in mainland China. The Company will fully provide technology, sales and operation services in mainlandChinaand the Asia-Pacific market. Meanwhile, in adhering to the European manufacturing concept, it will also vigorously promote its quality lubricants in the Asia-Pacific market!